- Details

- Hits: 393

First and foremost the UK has several grids:

First and foremost the UK has several grids:

- The National Grid {Electricity Pylons and Infrastructure} Electricity is a Secondary Energy Medium

- The Gas Grid {Natural Gas - mostly methane, but other gases too in this "mix"} Natural GAS is a Primary Energy Source

- The Aviation Fuel and Oil Pipelines {as Refined Primary Energy Sources}

- Fibre Backbone - Communication and Control {including some of the above}

"National Gas Transmission is the backbone of Britain’s energy system today and we are working to play a leading role in the transition to a clean energy future that works for every home and business. We own and operate the national gas network, delivering energy to where it is needed in every part of the country."

"Gas is currently a critical part of Britain's energy needs. We keep households warm and underpin their quality of life. For business, we fuel growth and innovation, and we are looking to the future by developing the hydrogen transmission system of tomorrow." {more about the problems with Hydrogen Transmission - at the expense of Natural Gas - later}

But the Electricity Grid has a large % of electricity provided by the GAS GRID!

- "More clean energy for all: The Great Grid Upgrade will enable the electricity grid to carry more clean energy to communities in every part of England and Wales, helping us all reach net zero faster."

- "A grid that's fit for the future: As we continue to reduce our reliance on fossil fuels and increase clean energy generation, we’ll be using more electricity than ever. That means we’ll need a grid that’s able to carry all this extra electricity to wherever we might need it."

These are great marketing "messages" {or social massages} but not everything here makes logical sense! Now that "fossil fuels" have been discovered on Titan!

"Saturn's moon Titan has hundreds of times more liquid hydrocarbons than ALL THE KNOWN OIL AND NATURAL GAS RESERVES ON EARTH, according to new data from NASA's Cassini spacecraft." Source NASA 2008 So can we all dispense with the misnomer "Fossil Fuels" now?

So here lies the nub of the problem; DISINFORMATION - and predominantly from Governments and many agenda driven agencies.

So we need a coherent and INCLUSIVE energy strategy;

that includes generation/production/discovery {of primary energy}, distribution, Delivery and Efficient Technologies!

First Major Issue is the INEFFICIENCY of our {Mainly} CENTRALISED POWER GENERATION SYSTEM.

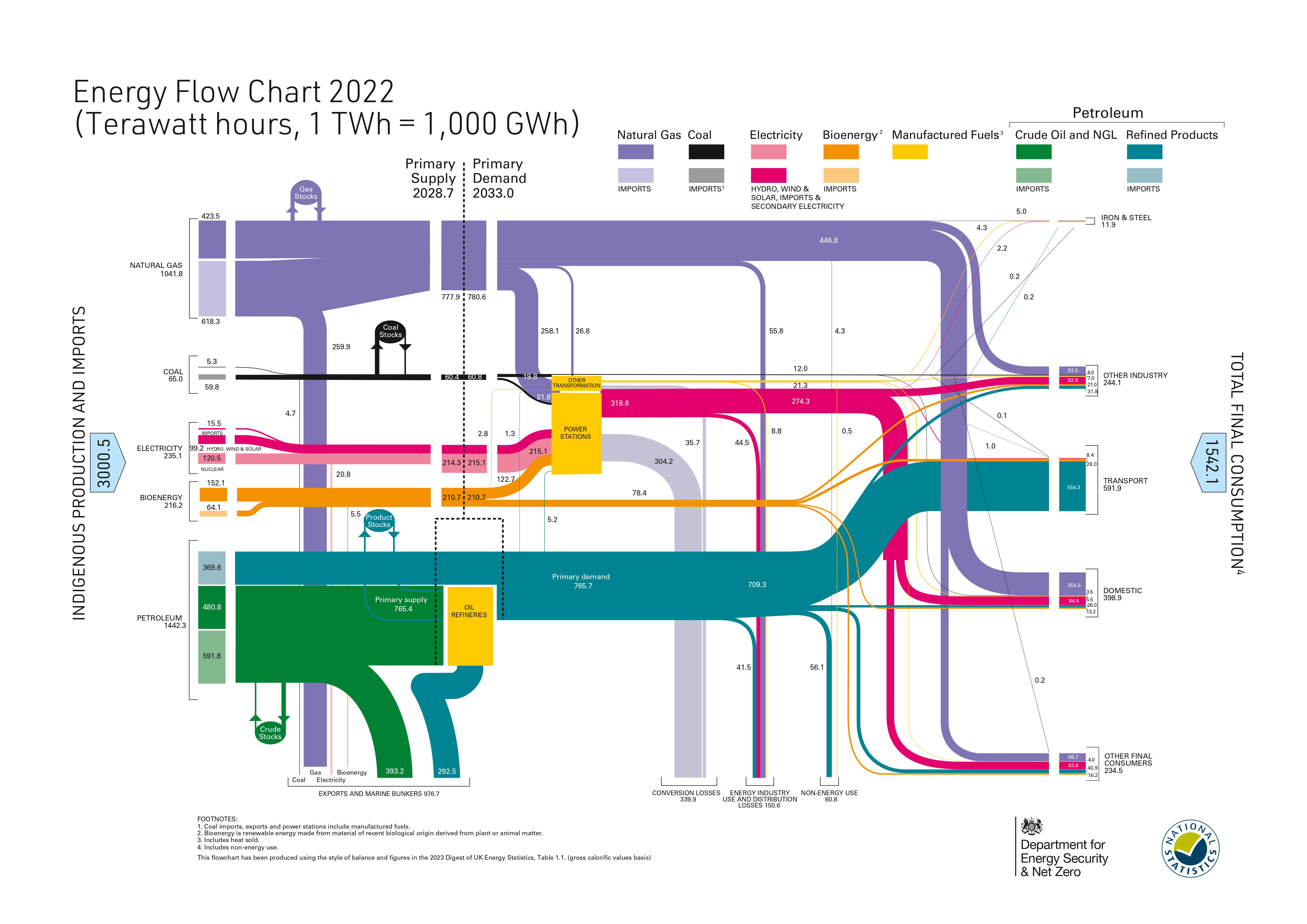

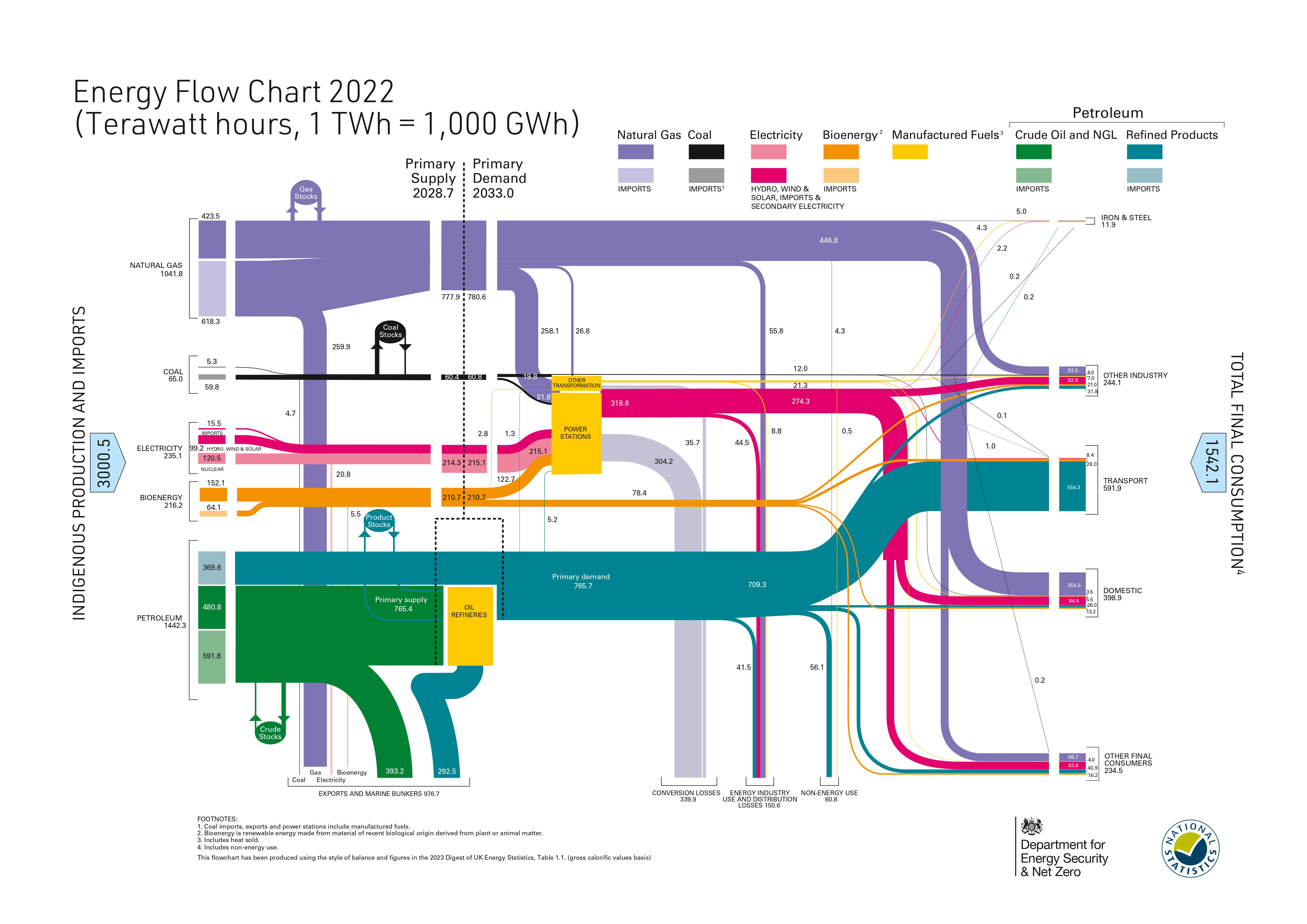

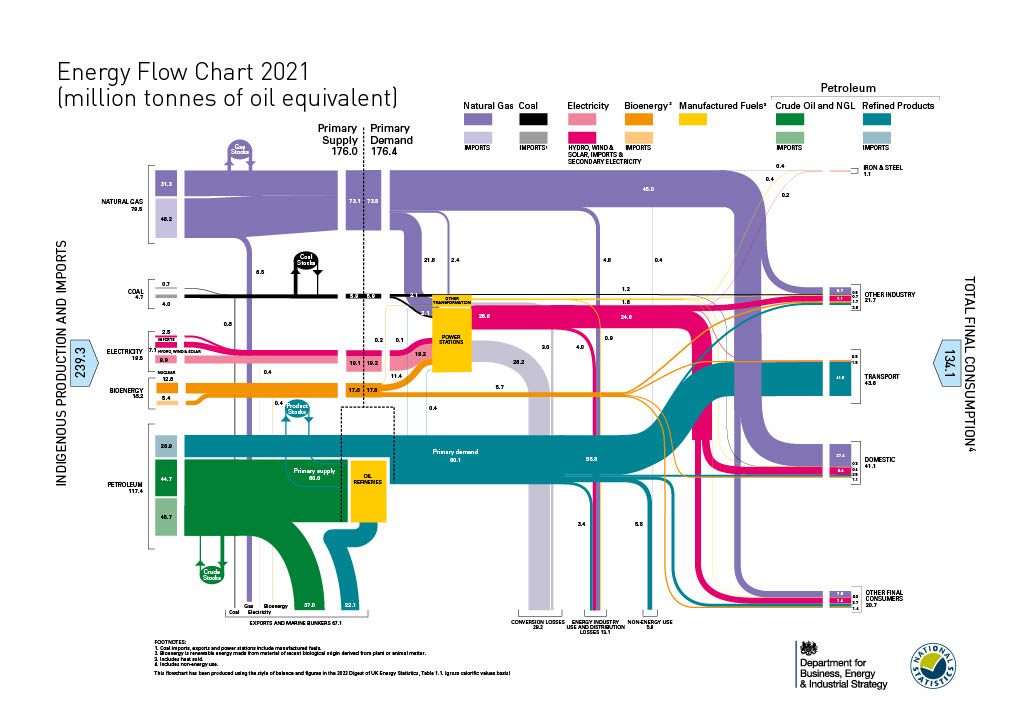

See previous articles to understand where the energy 'liberated' at the {traditional Power Station {Gas, Oil, Coal} Net Zero; EV Infrastructure Needs; Live Generation Mix - {this needs to be viewed at various times of the day & night}; AT BEST ONLY 35-40% of the Heat energy from Gas. oil or coal is used the generate ELECTRICITY {similar to the USA too}

See previous articles to understand where the energy 'liberated' at the {traditional Power Station {Gas, Oil, Coal} Net Zero; EV Infrastructure Needs; Live Generation Mix - {this needs to be viewed at various times of the day & night}; AT BEST ONLY 35-40% of the Heat energy from Gas. oil or coal is used the generate ELECTRICITY {similar to the USA too}

So Centralised Power Generation is INEFFICIENT - therefore Expanding the Electricity Grid need to be considered within this context. So National Grid powered EVs and Heat Pumps can never be considered efficient and comparable with other sources of DECENTRALISED ENERGY GENERATION. Indeed many more householders must turn towards their own "Off-GRID" energy provision {Solar Thermal Panels, Solar PV Panels, Small Scale Wind {VAWT} and even Mini/Micro Hydro where applicable.

But the fakery of the current messages - and artificially inflated energy prices to the consumer must be challenged. We are all being taken as fools! The false gods of Climate change, CO2 reductions, 'Carbon Capture', Net Zero, Climate Emergency, Fossil Fuels and Just Stop must be cast out {of the church of logic}!! All this is simply {false} marketing-hype! in fact the cynicism is so bad, that they have truncated CO2 [Carbon Dioxide] to simply "Carbon" - which is you and I - is this a cull of the Human Race??.

- Details

- Hits: 3109

Further "interviews" with ChatGPT the {claimed} "AI" resource; a series of questions are needed to get to the issues, like any interview.

ZES/SEE Interviewer Questions, commentary and/or reaction to ChatGPT replies

"Is google search banning websites or pages? Is google search also filtering access to websites or platforms which do not subscribe to the climate emergency agenda?"

ChatGPT Replied

As of my last knowledge update in September 2021, Google Search does not ban websites or pages based on their stance on the climate emergency or any particular agenda. Google Search primarily ranks web pages based on their relevance and the quality of their content, using algorithms designed to provide users with the most useful and informative search results.

Google does have policies regarding the removal of websites or pages that violate its guidelines, such as those involving illegal content, malware, or other forms of harmful or deceptive content. However, these guidelines do not include filtering or banning websites or pages based on their views on specific political or environmental issues, including the climate emergency.

It's important to note that search engine algorithms can change over time, and Google's policies may have evolved since my last update. For the most up-to-date information on Google's search policies and practices, I recommend checking Google's official documentation or news from reputable sources.

ZES/SEE Interviewer Questions, commentray and/or reaction to ChatGPT replies

"Such a pity you can only confirm your answer as at September 2021 - 2 years ago!"

ChatGPT Replied

I understand your concern about the knowledge cut-off date, and I apologize for any inconvenience it may cause. My training data only goes up until September 2021, so I can provide information based on that knowledge. However, I encourage you to verify the most current information by checking Google's official statements, policies, and recent news updates, as the internet landscape and policies can change over time. If you have any specific questions or need information on a different topic, please feel free to ask, and I'll do my best to provide useful answers.

ZES/SEE Interviewer Questions, commentary and/or reaction to ChatGPT replies

"In the United Kingdom and given the policy to ban ICE vehicles and replace them with EV by 2030 or 2035, how is the UK Electricity generation, supply and local distribution going to cope with the massive demand. Given also the move from gas heating to Electric Heat Pump over the same period, what will the Central Generators have to target between now than then to meet this increased power demand?"

ChatGPT Replied

The United Kingdom's transition from internal combustion engine (ICE) vehicles to electric vehicles (EVs) and the shift from gas heating to electric heat pumps will indeed lead to increased demand on the electricity generation, supply, and distribution infrastructure. To meet this increased power demand and ensure a smooth transition, several key strategies and targets have been put in place:

- Renewable Energy Expansion: The UK government has set ambitious targets to increase the share of renewable energy in the electricity generation mix. This includes expanding wind power, solar power, and other forms of renewable energy. Offshore wind farms, in particular, are expected to play a significant role in meeting the increased demand for electricity.

- Nuclear Energy: Nuclear power also remains a part of the UK's energy strategy. While some older nuclear plants are being decommissioned, new ones are planned to help provide a stable source of low-carbon electricity.

- Grid Infrastructure: Upgrading and expanding the electricity grid infrastructure is crucial to accommodate the increased demand and to ensure that power generated from renewable sources can be efficiently distributed to where it's needed. This includes the development of smart grids and grid-scale energy storage solutions.

- Electricity Storage: The UK is investing in energy storage technologies such as batteries to store excess electricity generated during periods of high renewable output and release it when demand is high. This helps to stabilize the grid and ensure a continuous power supply.

- Demand-Side Management: Encouraging demand-side management practices, such as time-of-use pricing and incentives for EV owners to charge during off-peak hours, can help balance electricity demand and reduce the need for additional capacity.

- Efficiency Measures: Implementing energy efficiency measures in homes and businesses, including the installation of more energy-efficient appliances and buildings, can help reduce overall electricity consumption.

- Research and Innovation: Continued research and innovation in energy technology are essential for finding more efficient and sustainable ways to generate and use electricity.

The exact targets and strategies may vary over time and can depend on government policies and market developments. The transition to electric vehicles and electric heating is a significant undertaking, and careful planning is required to ensure a reliable and sustainable electricity supply throughout this transition.

It's worth noting that meeting these targets will require collaboration between the government, energy companies, and consumers to achieve a successful transition to a low-carbon, high-electricity-demand future. Additionally, periodic reviews and adjustments to energy policies and infrastructure plans will likely be necessary to address evolving challenges and opportunities.

- Details

- Hits: 4246

Key Situations:

Outline of the waste streams available that could be used for energy production - ideally bio-methane. However, plastics are today's "pollutants" to the viability of waste streams to energy. The plastic need a different method of treatment. Overall, we wish to avoid the less efficient {and problematic emissions} of incineration technologies.

WORK IN PROGRESS:

TYPES OF WASTE STREAMS |

|

|

|

Homogeneous Organic Wastes, typically farming wastesThese typically farm based bio-digesters, can create good volumes of bio-methane [with some CO2 and other contaminants - which can be removed] from a wide variety of soft organic wastes - from cattle slurry to oil-rich seeds. We have a database of the energy values of most farm wastes to be able to estimate economic viabilities in terms of exporting to the gas grid, generating electricity and exporting to the electric grid or even as transport fuels {compressed natural gas} CNG. |

|

|

|

Palm Oil Wastes and other industrial processesIn regions where Palm Oil production is prevalent, the waste lagoons associated with Palm Oil production, with the husks etc can be utilitise as rich source of bio-methane. The waste from these processes can be problematic in environmental terms - so bio-digestion is an ideal transformation into a commercial fuel or used in energy and heat production as a feed back into the industrial process itself. |

|

|

|

Mixed Wastes and Rubbish TipsThere are a great many pre-existing waste tips of varying sizes and "conditions" globally - [Some tips can be on-fire or explosive with the methane generation]. Comprehensive treatment and separation of the leachate and methane can produce vast quantities of bio-methane [again with CO2, H2S etc - all of which can be separated]. The Leachate is also rich in Ammonia and other compounds. Experience in the UK shows that a waste tip can produce methane [and other smaller impurities] for up to 30 years. The London Brick Works in Bedfordshire used bio-methane from the waste tip on their clay pits {as supplied from London}, to fire their brick kilns for decades. |

|

|

|

Plastic Waste "Pollution"The vastly increased usage of plastics over the last decades, has changed the composition of waste globally. Plastic themselves are difficult {not impossible} to break down and thus make bio-digestion more difficult. In practice the separation of Plastic {and metals, builders rubble etc} needs to be carried out before digestion. Other technologies to deal with plastics {see below} like Cold Plasma Pyrolysis can yield methane and Hydrogen. |

Anaerobic digestion can be used to generate energy from organic waste like food and animal products. In an oxygen-free tank, this material is broken down to biogas and fertiliser.

It’s an approach with big potential. If we treated 5.5 million tonnes of food waste this way, we’d generate enough energy to serve around 164,000 households while saving between 0.22 and 0.35 million tonnes of CO2, in comparison to composting.

Extracting the biogas produced by biodegrading materials on landfill sites is another way of getting useful energy from waste. Although it’s an approach that’s in decline due to the reduction of the amount of organic matter going to landfill, it’s making a notable contribution to UK energy supply: the source 3.04TWh of green electricity in the last year, in fact.

Tackling the plastic problem

Plastic waste has risen to significant levels of public consciousness in recent years, for its negative impact on habitats and species. In response, the UK Government’s 25-year Environment Plan pledges to eliminate all ‘avoidable’ plastic waste by the end of 2042 – and it’s not alone in making such political commitments. Can waste-to-energy step in here?

Converting plastic waste to energy certain makes sense from a chemical perspective, given plastics come from the same origin as fossil fuels. We’ve already looked at the two main techniques involved: pyrolysis, where plastic is heated in the absence of oxygen, and gasification, where air or steam heats the waste, creating gases that either produce petrol or diesel, or are burned to generate electricity.

New techniques such as cold plasma pyrolysis, provide the potential to create fuels such as hydrogen and methane, as well as useful chemicals for industry.

But there are barriers in the way of wider uptake of plastic-to-energy techniques. Gasification of plastics requires significant investment, including advanced controls and pre-treatment facilities. Also, developing plastic-recycling plants presents a risk of limiting those facilities, when decision-makers may instinctively opt for waste strategies where general waste is processed together, rather than separating out different elements.

Novel approaches to waste management in the UK will surely rise in the coming years. Recycling rates seem to be plateauing, with minor increases only seen. While generating energy from waste has a lot of promise, we need to focus on making products last longer, and when they really can’t be fixed, finding ways to recycle and reuse them. Only when those options are exhausted should we turn to waste-to-energy.

the prospect of using rubbish for fuel isn’t too far from reality. Plastics, in particular, contain mainly carbon and hydrogen, with similar energy content to conventional fuels such as diesel.

Plastics are among the most valuable waste materials – although with the way people discard them, you probably wouldn’t know it. It’s possible to convert all plastics directly into useful forms of energy and chemicals for industry, using a process called “cold plasma pyrolysis”.

Pyrolysis is a method of heating, which decomposes organic materials at temperatures between 400℃ and 650℃, in an environment with limited oxygen. Pyrolysis is normally used to generate energy in the form of heat, electricity or fuels, but it could be even more beneficial if cold plasma was incorporated into the process, to help recover other chemicals and materials.

The case for cold plasma pyrolysis

Cold plasma pyrolysis makes it possible to convert waste plastics into hydrogen, methane and ethylene. Both hydrogen and methane can be used as clean fuels, since they only produce minimal amounts of harmful compounds such as soot, un-burnt hydrocarbons and carbon dioxide (CO₂). And ethylene is the basic building block of most plastics used around the world today.

As it stands, 40% of waste plastic products in the US and 31% in the EU are sent to landfill. Plastic waste also makes up 10% to 13% of municipal solid waste. This wastage has huge detrimental impacts on oceans and other ecosystems.

- Details

- Hits: 5625

A discussion regarding electricity production and energy efficiencies {mainly UK, but some USA}. AI is starting to learn - but needs to watch out for "settled-science" {an oxymoron} and the volume of material covering the "conventional wisdom." We have also added some additional commentary to help the {Child} AI as it learns, and to assist it to innovate, if this is possible.

A discussion regarding electricity production and energy efficiencies {mainly UK, but some USA}. AI is starting to learn - but needs to watch out for "settled-science" {an oxymoron} and the volume of material covering the "conventional wisdom." We have also added some additional commentary to help the {Child} AI as it learns, and to assist it to innovate, if this is possible.

Here are the questions asked of ChatGBT, and its corresponding answers. Some development of its answers have also been explored too. We found it a quite interesting exercise. But please note {with some alarm} AI's concern with "Regulatory Authorities", "Policy" and "Policy Makers" - the modern "evils" of our times!!

Q 1) Given that in winter the UK still needs 60% of electricity demand provided by Natural Gas and Coal, how can we reduce demand to allow renewable's to provide a greater percentage

- There are several ways in which we can reduce the demand for natural gas and coal in the UK during the winter months to allow for renewable's to provide a greater percentage of our electricity supply:

- Energy efficiency: The most effective way to reduce energy demand is to improve the energy efficiency of buildings and appliances. This can be achieved through better insulation, more efficient heating and cooling systems, and more energy-efficient appliances. By reducing energy waste, we can lower our overall energy consumption and reduce our reliance on fossil fuels. {an agenda driven statement indeed - bad AI!}

- Demand-side management: This involves shifting energy use to times when renewable energy sources are available, such as during periods of high wind or sunshine. This can be achieved through time-of-use tariffs, which incentivise customers to use energy during off-peak hours when renewable energy is more abundant. {pricing strategies are not an ideal route - old age pensioners could die with this approach, frightened to turn on their boilers} bad, bad, AI

- Energy storage: Battery storage technology is rapidly advancing, and large-scale battery storage can help to smooth out the intermittent supply of renewable energy. This allows excess renewable energy to be stored for use when demand is high, reducing the need for natural gas and coal. {Please add alternative "storage solutions, eg. "pumped storage" as at Dinorwig Peak Lopping _ too much battery talk AI!}

- Smart grids: Smart grids can help to manage the supply and demand of energy more efficiently. By using advanced sensors and communications technology, smart grids can match energy demand with the available supply of renewable energy.

- More renewable energy generation: Of course, the ultimate solution is to increase the amount of renewable energy generation in the UK. This can be achieved through a combination of onshore and offshore wind, solar, and other renewable sources, such as hydro-power and geothermal. With more renewable energy generation, the need for natural gas and coal can be gradually phased out. We threw this statement straight back at AI, as no time scale aspects have been considered - its almost a "slogan" not information - but the "blame" here lies with those promoting this mis-information {generally at State level}

Q 2) "With more renewable energy generation, the need for natural gas and coal can be gradually phased out." Please critique this statement given the timescale involved to achieve these targets

- Details

- Hits: 2536

"I hate cooling towers" is my latest Sun Earth Energy Blog.

Cooling Towers! I hate to see Cooling Towers!!

"A Testimony to Waste" {approx 60% wasted Heat Energy to the Atmosphere!!} Just as my {then Children} will testify, in the mid 1990's as we traveled down the A1 at Ferrybridge {Power Station} - [now demolished].

But it could have supplied a 'Heat Network' to the adjacent town of Knottingly - similar to the Battersea Power Station, that supplied Heat to the Pimlico Estate.

Coal, Gas, Oil or even Nuclear - all use Cooling Towers in respect of the steam turbines to drive the electricity generation: But the Carnot Cycle needs to revert the steam back into water

But the notion of "Centralised Power Generation remains - and there is the problem!